SiC Heat Exchangers Back

Products

www.bartcompany.com

www.bartcompany.com

Description

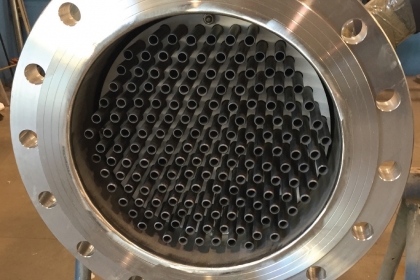

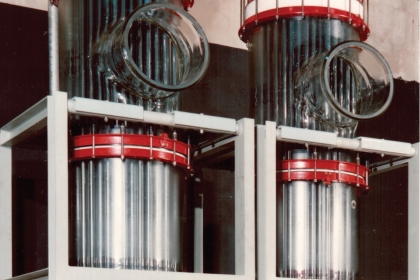

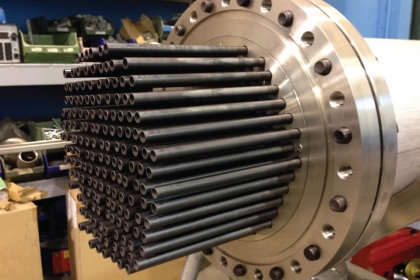

SuperSiC® and BaSiC® heat exchangers with silicon carbide tubesheet and tubes are the top answer to severe corrosive applications. Ideal for heating, cooling and condensing chemically aggressive process streams. Typical applications include: bromine, sulphuric, hydrofluoric, nitric, hydrochloric and other acids; caustic and other alkalis; halogenated compounds; salt solutions, and organic compounds. All process side parts are made of SiC and/or PTFE SiC-filled.

Advantages of Silicone carbide (SiC):

CE, ATEX, ASME, FDA full compliance.

Silicon carbide is unsurpassed in fighting corrosion.

Inert to virtually every type of chemical, silicon carbide is an ideal material for handling corrosive media.

Unlike graphite, Silicon Carbide contains no binders to leach out in corrosive solutions.

The well-known non stick properties of silicon carbide help minimize fouling and scaling that would reduce heat transfer rates of metal and graphite.

Silicon carbide material is resistant to damage resulting from thermal shock; outperforms glass and graphite.

When necessary, units can be cleaned on-site chemically of mechanically with minimal downtime.

Double TubeSheet Design: it is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids.

This chamber can be pressurized at a higher pressure than the process one to avoid leaking in case of o-ring failure.

SuperSic

each tube is tested at 185 Bar before installation

shell diameters for standard units range from 4” to 20” (100 – 500 mm)

shells are available in carbon steel, stainless steel, glass lined steel, PTFE lined steel, borosilicate glass

nominal tube length is from 1000 to 6000 mm

surfaces from 0,5 to 95 m2

tubing diameter Ø 12,7 mm Ø 14 mm, Ø 19 mm

single pass or multi pass design

double Tubesheet design (GMP)

horizontal or vertical installation

temperature range from –30°C to +320°C

pressure range from –1 Bar to +12 Bar

Special features on request.

CE, ATEX, ASME code, FDA full compliance.

Double Tubesheet Design It is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids. This chamber can be pressurized at a higher pressure than the than the process one to avoid leaking in case of o-ring failure.

BaSic

Tubesheet material: pure, vergin, PTFE 25% SiC filled

each tube is tested at 185 Bar before installation

shell diameters for standard units range from 4” to 20” (100 – 500 mm)

shells are available in carbon steel, stainless steel, glass lined steel, PTFE lined steel, borosilicate glass

nominal tube length is from 1000 to 6000 mm

surfaces from 0,5 to 95 m2

tubing diameter Ø 12,7 mm Ø 14 mm, Ø 19 mm

single pass or multi pass design

double Tubesheet design (GMP)

horizontal or vertical installation

temperature range from –30°C to +320°C

pressure range from –1 Bar to +12 Bar

Special features on request.

CE, ATEX, ASME code, FDA full compliance.

Advantages of Silicone carbide (SiC):

CE, ATEX, ASME, FDA full compliance.

Silicon carbide is unsurpassed in fighting corrosion.

Inert to virtually every type of chemical, silicon carbide is an ideal material for handling corrosive media.

Unlike graphite, Silicon Carbide contains no binders to leach out in corrosive solutions.

The well-known non stick properties of silicon carbide help minimize fouling and scaling that would reduce heat transfer rates of metal and graphite.

Silicon carbide material is resistant to damage resulting from thermal shock; outperforms glass and graphite.

When necessary, units can be cleaned on-site chemically of mechanically with minimal downtime.

Double TubeSheet Design: it is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids.

This chamber can be pressurized at a higher pressure than the process one to avoid leaking in case of o-ring failure.

SuperSic

each tube is tested at 185 Bar before installation

shell diameters for standard units range from 4” to 20” (100 – 500 mm)

shells are available in carbon steel, stainless steel, glass lined steel, PTFE lined steel, borosilicate glass

nominal tube length is from 1000 to 6000 mm

surfaces from 0,5 to 95 m2

tubing diameter Ø 12,7 mm Ø 14 mm, Ø 19 mm

single pass or multi pass design

double Tubesheet design (GMP)

horizontal or vertical installation

temperature range from –30°C to +320°C

pressure range from –1 Bar to +12 Bar

Special features on request.

CE, ATEX, ASME code, FDA full compliance.

Double Tubesheet Design It is possible to separate the process fluid and the service fluid with a separation chamber, so that in case of o-ring leaking no mix will occur between the two fluids. This chamber can be pressurized at a higher pressure than the than the process one to avoid leaking in case of o-ring failure.

BaSic

Tubesheet material: pure, vergin, PTFE 25% SiC filled

each tube is tested at 185 Bar before installation

shell diameters for standard units range from 4” to 20” (100 – 500 mm)

shells are available in carbon steel, stainless steel, glass lined steel, PTFE lined steel, borosilicate glass

nominal tube length is from 1000 to 6000 mm

surfaces from 0,5 to 95 m2

tubing diameter Ø 12,7 mm Ø 14 mm, Ø 19 mm

single pass or multi pass design

double Tubesheet design (GMP)

horizontal or vertical installation

temperature range from –30°C to +320°C

pressure range from –1 Bar to +12 Bar

Special features on request.

CE, ATEX, ASME code, FDA full compliance.