Thin Film Evaporators / Short Path Evaporators Back

Products

www.kremsmueller.com

www.kremsmueller.com

Description

- Thin Film Evaporators

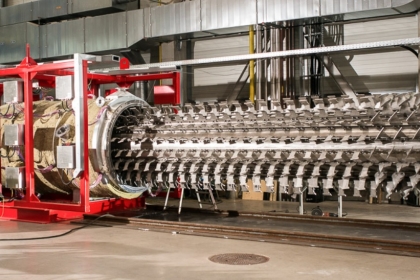

The stock solution is fed to the upper part of the thin film evaporator, and the scrapers of rotor distribute the liquid evenly over the heating surface in the form of a thin film with uniform thickness. This ensures a highly efficient heat transfer with simultaneous constant renewal of the feed material film, which contributes to uniform heating and short residence time of the material in the heating zone.

Various rotor / blade systems allow the selection of a perfect combination for the product to achieve a turbulent flow in the entire liquid film.

The resulting vapours enter the condenser and are condensed there. The quality of the product can be further increased by means of a packed column. The side vents allow the evaporator to be used separately or as a rectification column.

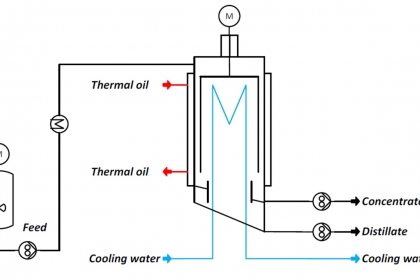

- Short Path Evaporator

Installing the condenser is in the evaporator reduces the loss of pressure between the heating and condensing surfaces to a few Pa, as the distance between these surfaces becomes extremely small, while maintaining a high percentage of evaporation. Operating pressure can be reduced to 0.005 mbar (0.5 Pa), which leads to a significant decrease in the boiling point of the liquid.

Evaporation using short path evaporator is a process of thermal separation for particularly temperature - sensitive products. Short residence time in the evaporator and low product temperature minimize the heat load on the product.

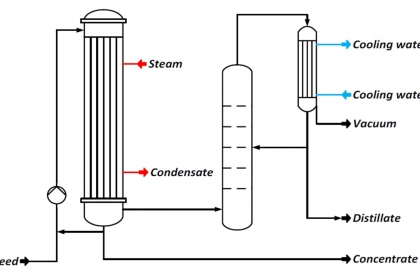

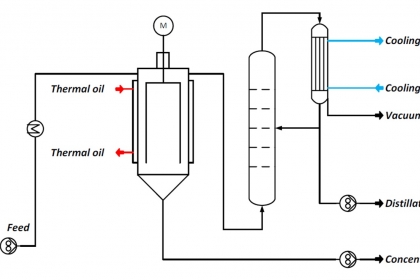

- Falling Film Evaporator

The stock solution is fed and distributed over the top of the evaporator. Under the influence of gravity, a thin liquid film flows along the inner side of the tubes / plates to the bottom of the apparatus. The energy required for evaporation is supplied by means of thermal oil or a vapour, heated by liquid. Due to heating, some of the liquid evaporates and enters the evaporator as a vapour. In order to further increase the purity of the product, the resulting vapours can be further passed through the rectification column. The steam condensate is then collected in a distillate tank, and the concentrate is removed from the bottom of the falling film evaporator.